The

compaction factor test is used for concrete which have low workability for

which slump test is not suitable.

The compacting factor

test is performed to ascertain the workability of the concrete. The slump test

does not give accurate results for low worability of concrete when slump is<50mm.

The compaction factor

test is a workability test for concrete conducted in the laboratory. It was

developed by the Road Research Laboratory in the United Kingdom and is used to

determine the workability of concrete.

The compaction factor is defined as the ratio of the weight of partially

compacted concrete to the weight of fully compacted concrete.

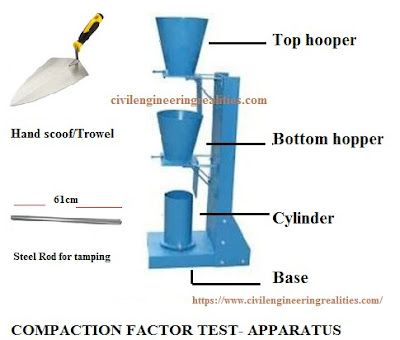

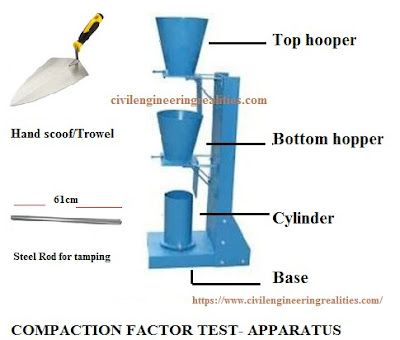

Compaction factor test Apparatus:-

Compaction factor test apparatus consists of two conical

hoppers and a bottom cylinder which is arranged properly

Steel rod of 1.6cm, diameter with a length of 61cm is is used to level

the concrete.

A weight balance is used to weight the concrete.

Hand

scoop (15.2 cm long) and a balance.

PROCEDURE:

1.Prepare

M15 grade concrete.the mixture with 1: 2: 4 by mixing the required amount of

water according to the water cement ratio and mix the fresh concrete.

2.See

that the inner surface of the conical hopper should be free of moisture and

apply grease to it. Close the trap door of the upper/top hopper.

3.Then

measure the weight of the empty bottom cylinder as W1.

4.Fill

fresh concrete into the upper/top conical hopper without disturbing the sample.

5.After

this, the trap door of an upper hopper is opened. Thus the concrete falls on

the lower/bottom hopper.

6.Wait

for 2-3 seconds and check if the entire concrete has fallen from the top hopper

to the bottom hopper. If not, a slight tamping is done until the entire

concrete falls into the bottom hopper.

7.Now

open the bottom hopper trap door, and the entire concrete has fallen on the

cylinder. Using the trowel, remove excess concrete on the top surface of the

cylinder.

8.Weigh

the cylinder with partially filled concrete as W2.

9.Then

the cylinder is emptied, and the concrete sample is filled again in 3 layers,

each layer being given 25 blows using a steel rod. Now, the concrete inside the

cylinder is completely compacted.

10.Measure

the weight of the cylinder completely with concrete as W3 .

Dimensions of compacting factor test apparatus

ADVANTAGES:

• Compression factor

test gives more information than slump test.

• The test is a dynamic

test and is thus more suitable for concrete mixture static tests.

DISADVANTAGES:

• The large and heavy

nature of the device reduces its usefulness in the field. In addition, the test

method requires an equilibrium to measure the mass of concrete in the cylinder.

• The amount of work

applied to the concrete being tested is a function of friction between the

concrete and the hopper, which probably does not reflect additional conditions.

• The test method does

not use vibration, the main compaction method used in the field.

• This test is commercially

available and is often used.

Calculation

of Compaction Factor Value:

The compaction factor is defined as

the ratio of the weight of partially compacted concrete to the weight of fully

compacted concrete.

Compacting Factor = (weight

of partially compacted concrete) / (weight of fully Concrete Concrete)

= W2 – W1 / W3

- W1

Here,

W1 = Weight of empty

cylinder.

W2 = Weight of partially

compacted concrete.

W3 = weight of fully

Concrete Concrete.

Result of Compaction Factor

Compaction factor of the

concrete =

The Compaction factor

values ranges from 0.7 to 0.95.

Compacting factor with respect to workability

Post a Comment